Quality Testing

Strict quality inspection process is key approach for HKSC's quality control system. We must ensure each step in the quality control process is strictlycarried out. We have advanced detection process, professional testing equipments and most importantly, the experienced QCs, professional and reliable working attitude, to ensure that our customers could receive the best quality products.

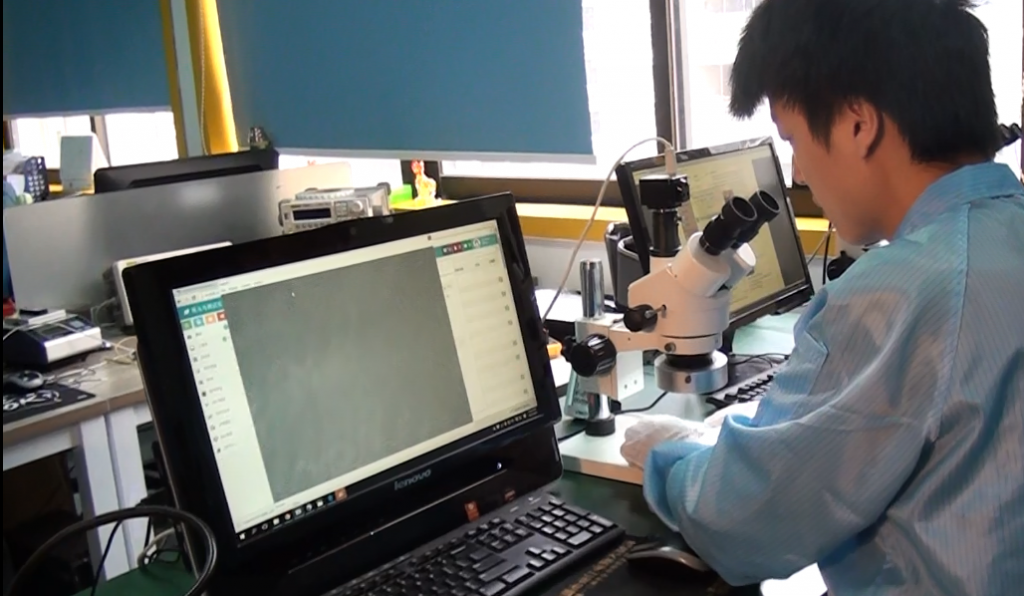

Step 1 - External Visual Inspection

|

We will perform visual inspection on all incoming goods and make detailed inspection records

|

Step 2 - Engineers Recheck

|

Every suspicious product during visual examination, or the product which is not from the 1st tier supplier will be re-examined by engineers. Referring to the quality control database, the manufacturer's label / logo, code identification will be checked.

wafer / package corresponding origin

|

Step 3 - Quality Test

|

Here the quality of the product will be tested:

|